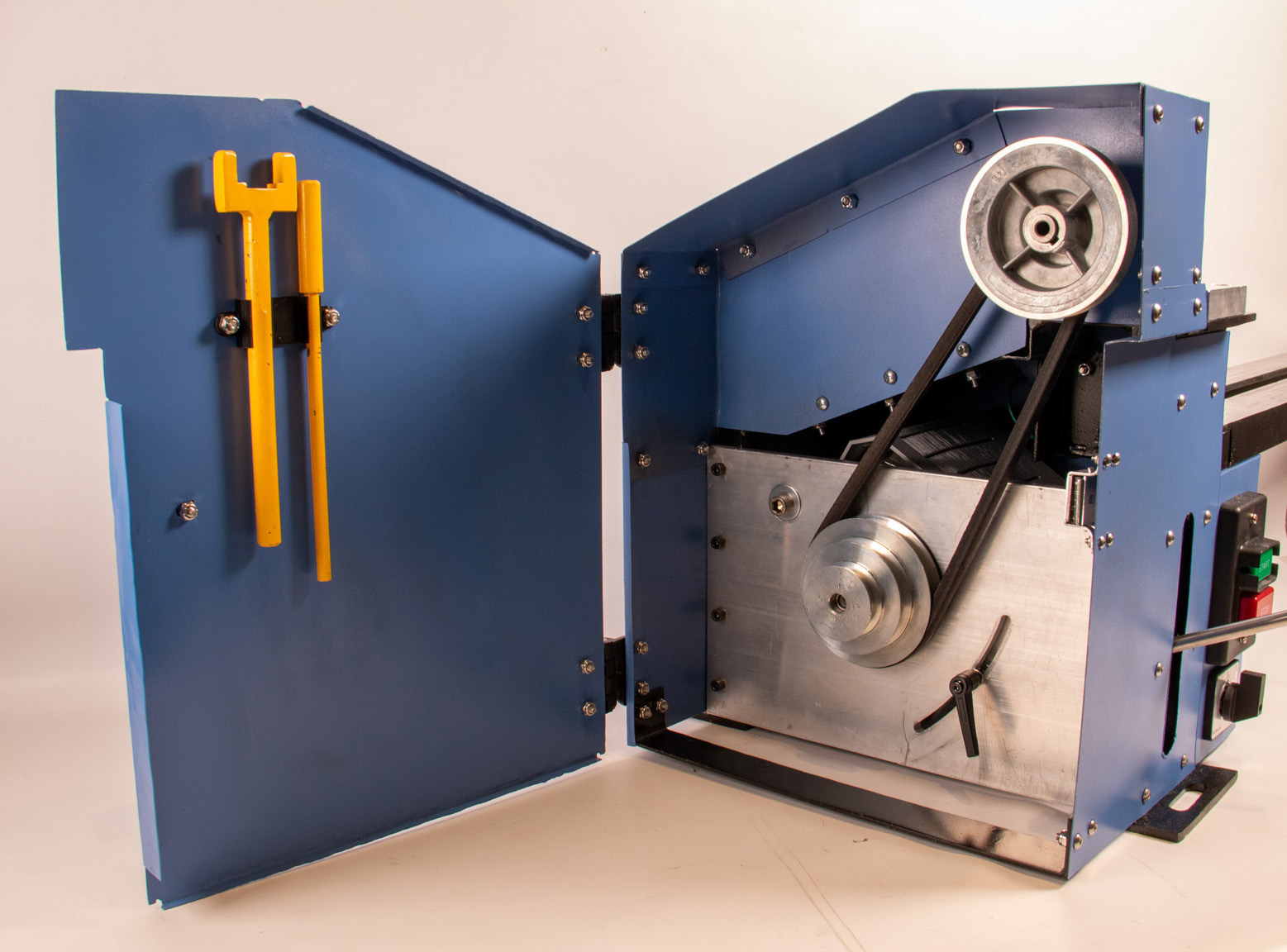

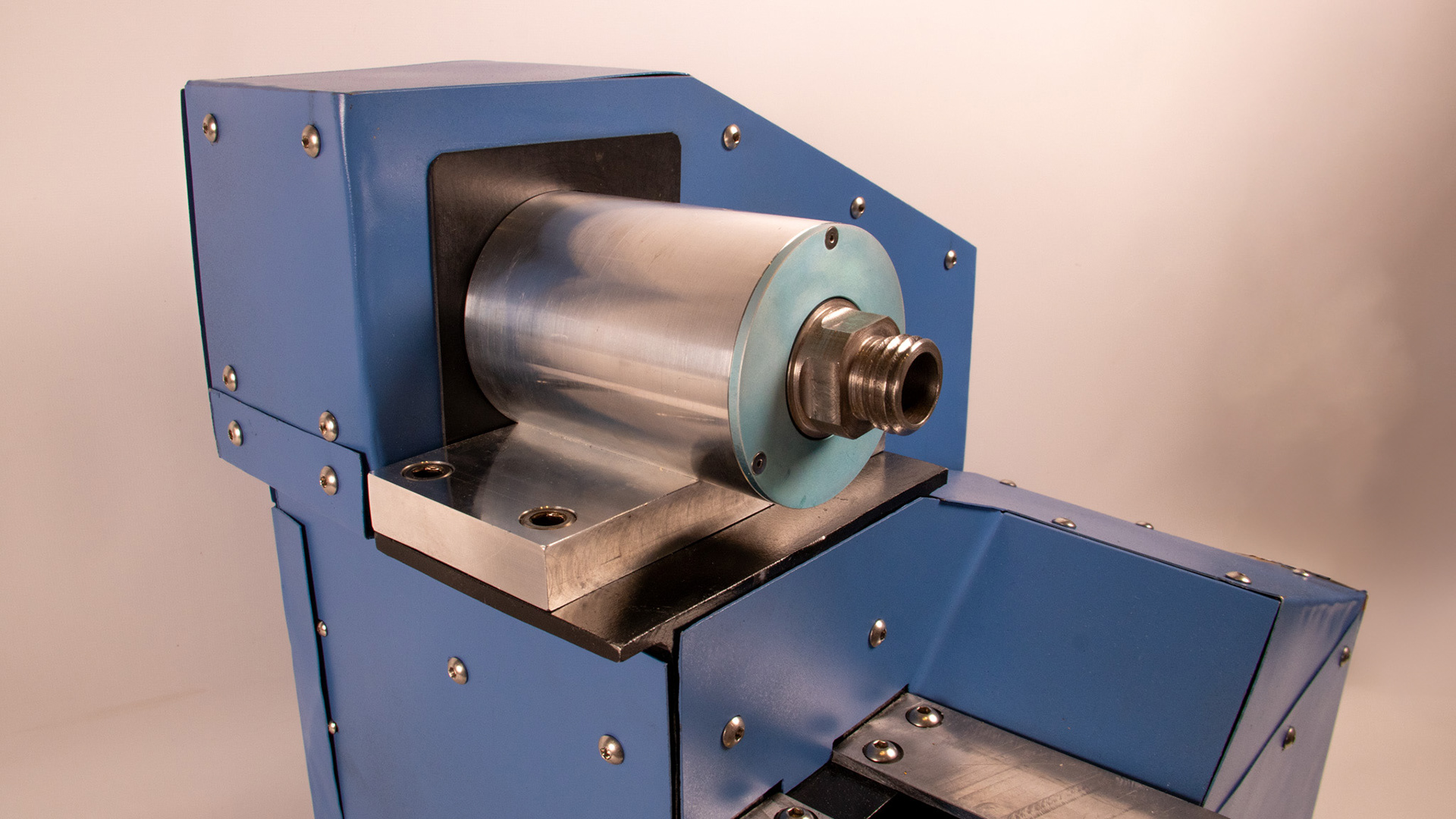

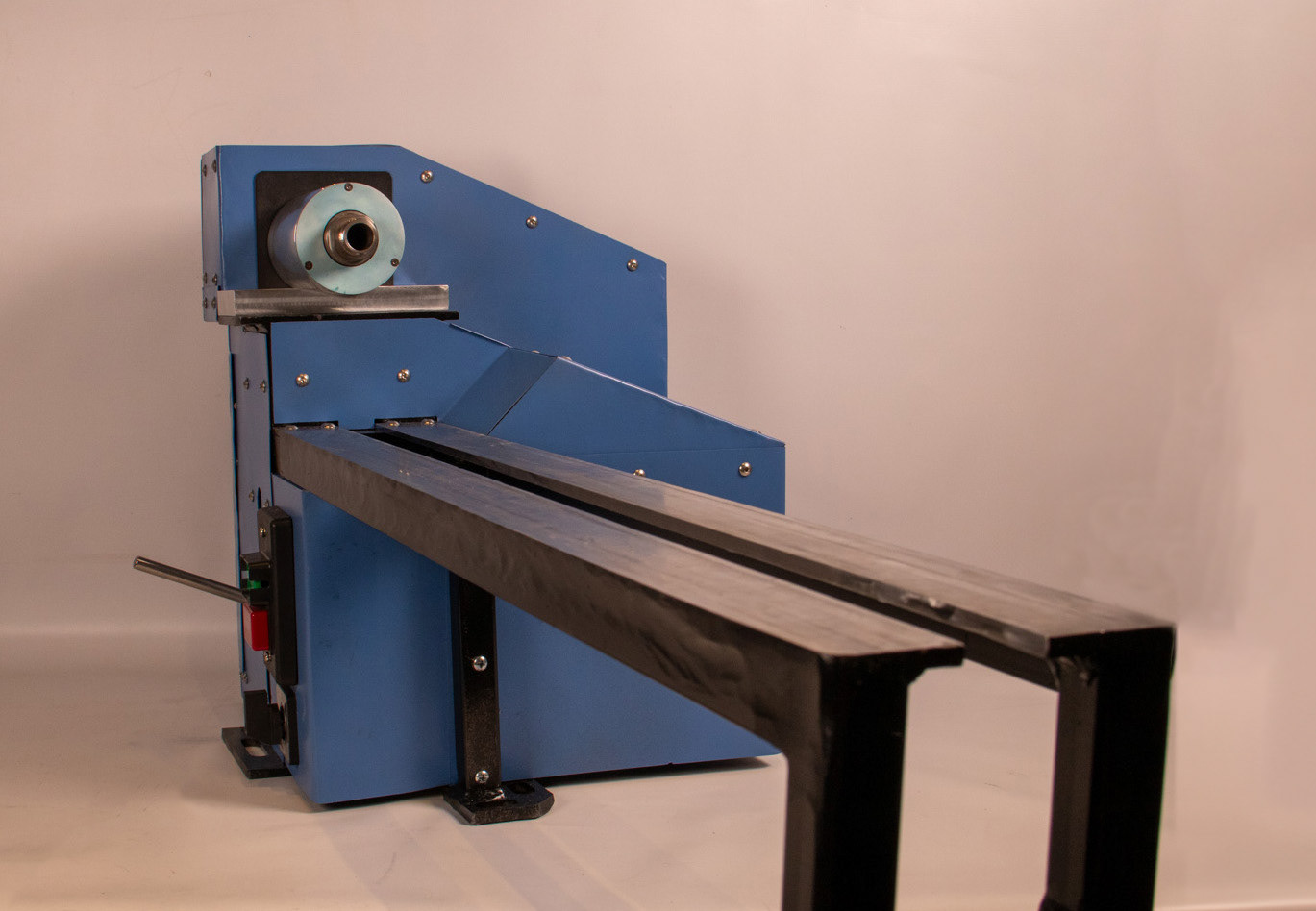

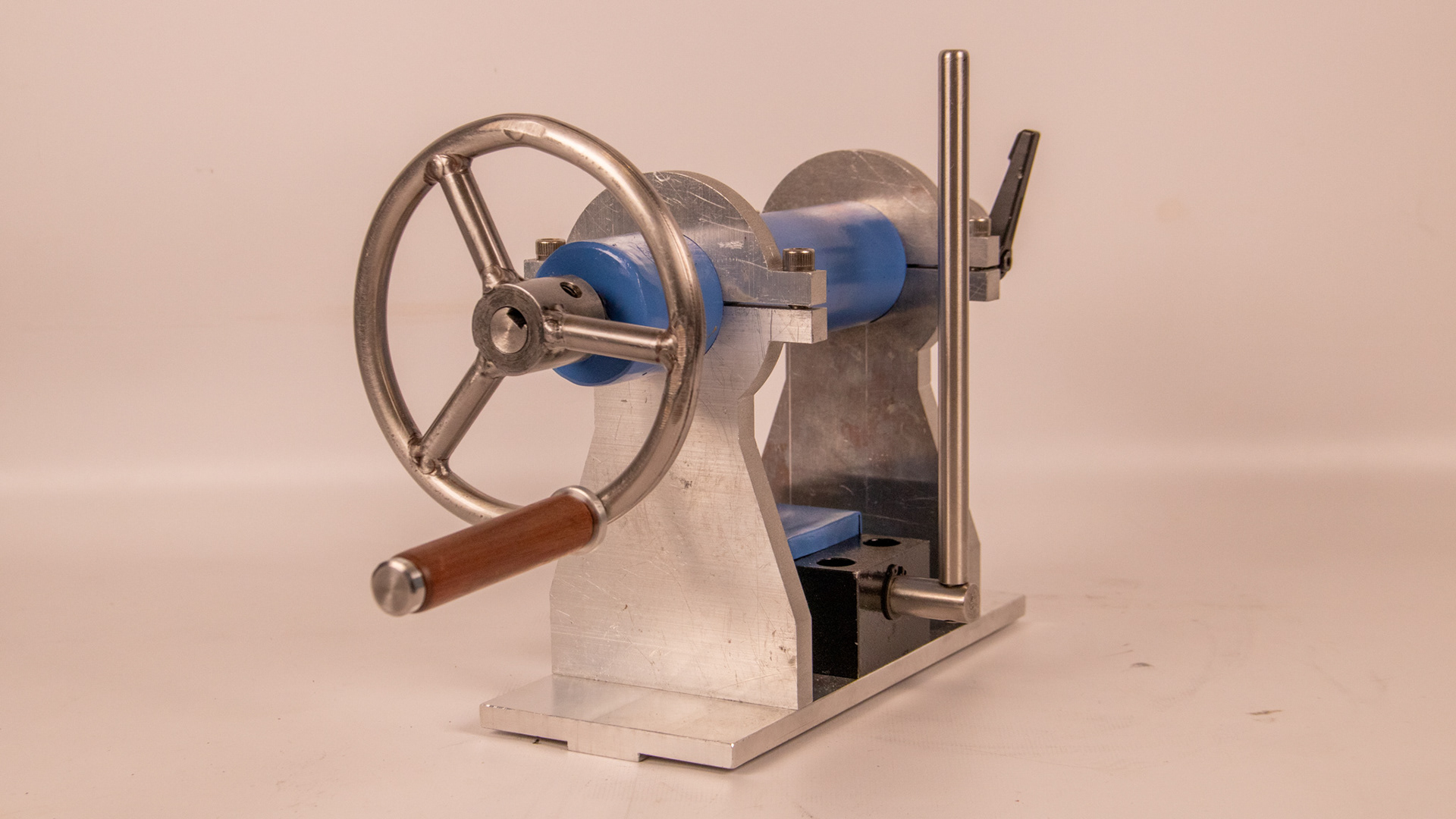

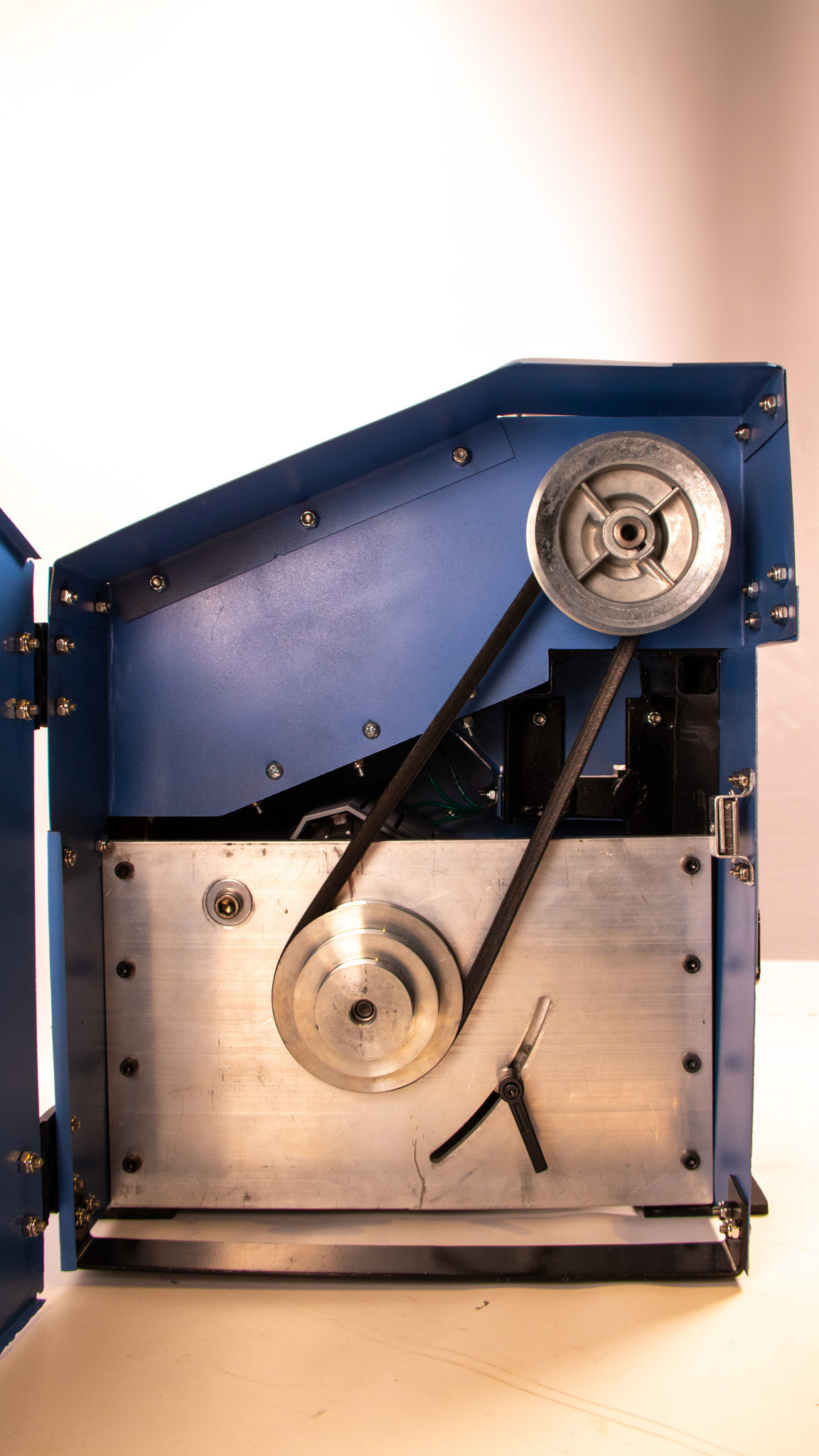

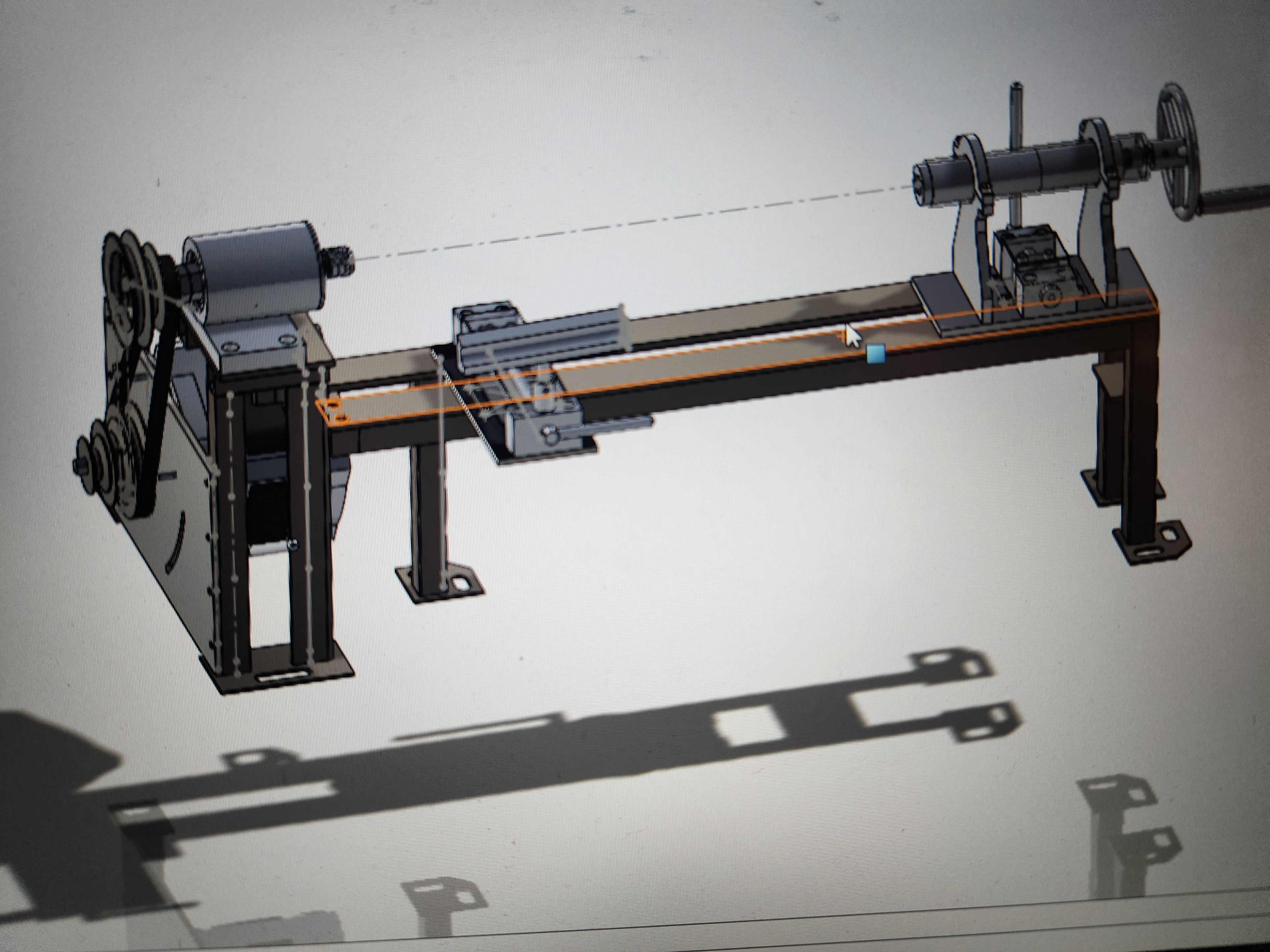

Custom designed and built wood lathe for Mechanical Design class. Worked with a team of 5 mechanical engineers. I was personally responsible for parts of the structure, the eccentric cam locks, the tool rest, the motor and electronics, and half of the tailstock. I spearheaded the fabrication efforts and could reliably be found working in the shop from opening to closing for weeks during finals.

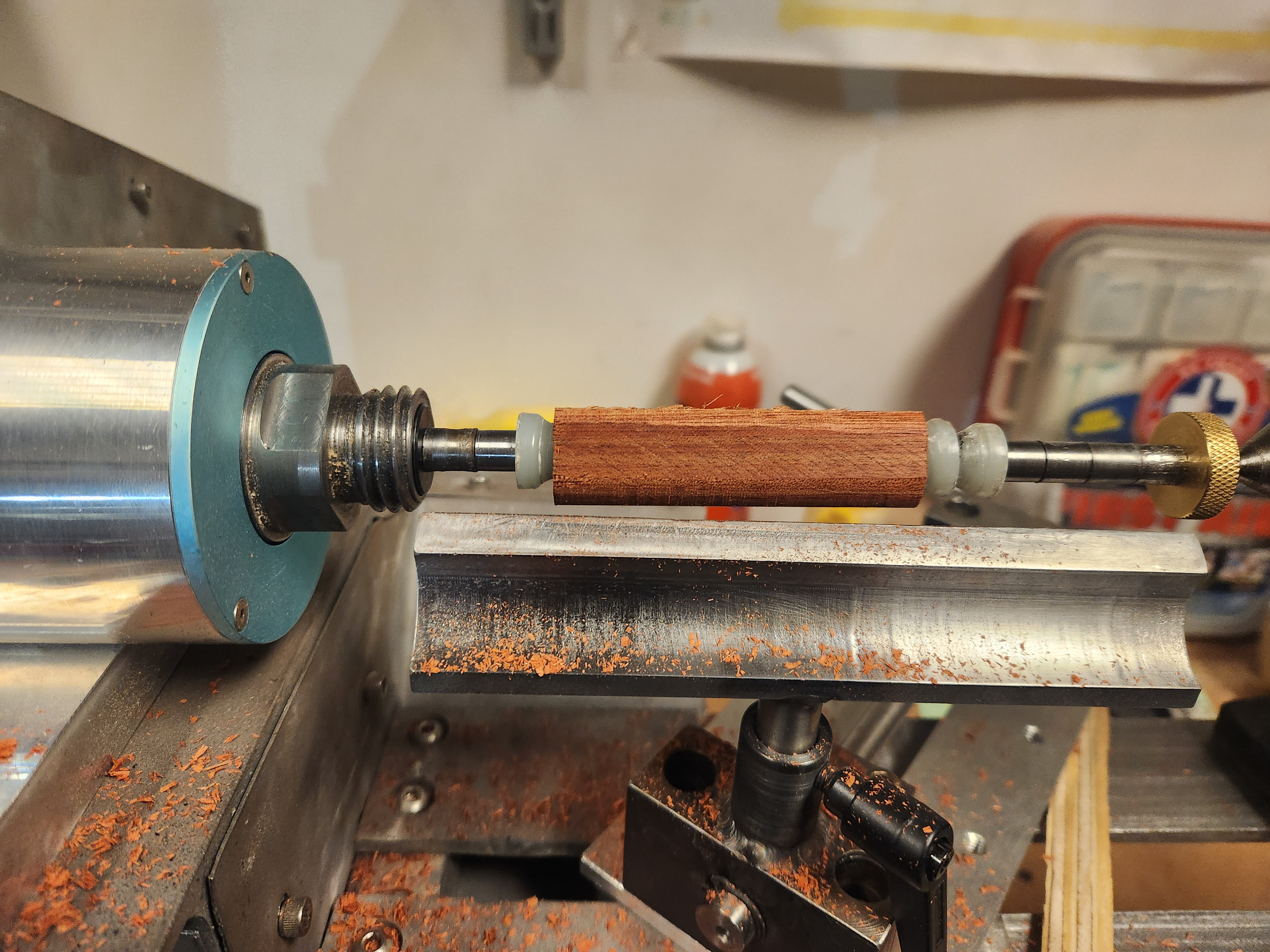

Using the lathe we designed and build I turned a pen for my uncles 80th birthday out of acrylic, and turned a beautiful wooden handle for the machines tailstock

Pen I turned for my uncles 80th Birthday on the Lathe I designed and built

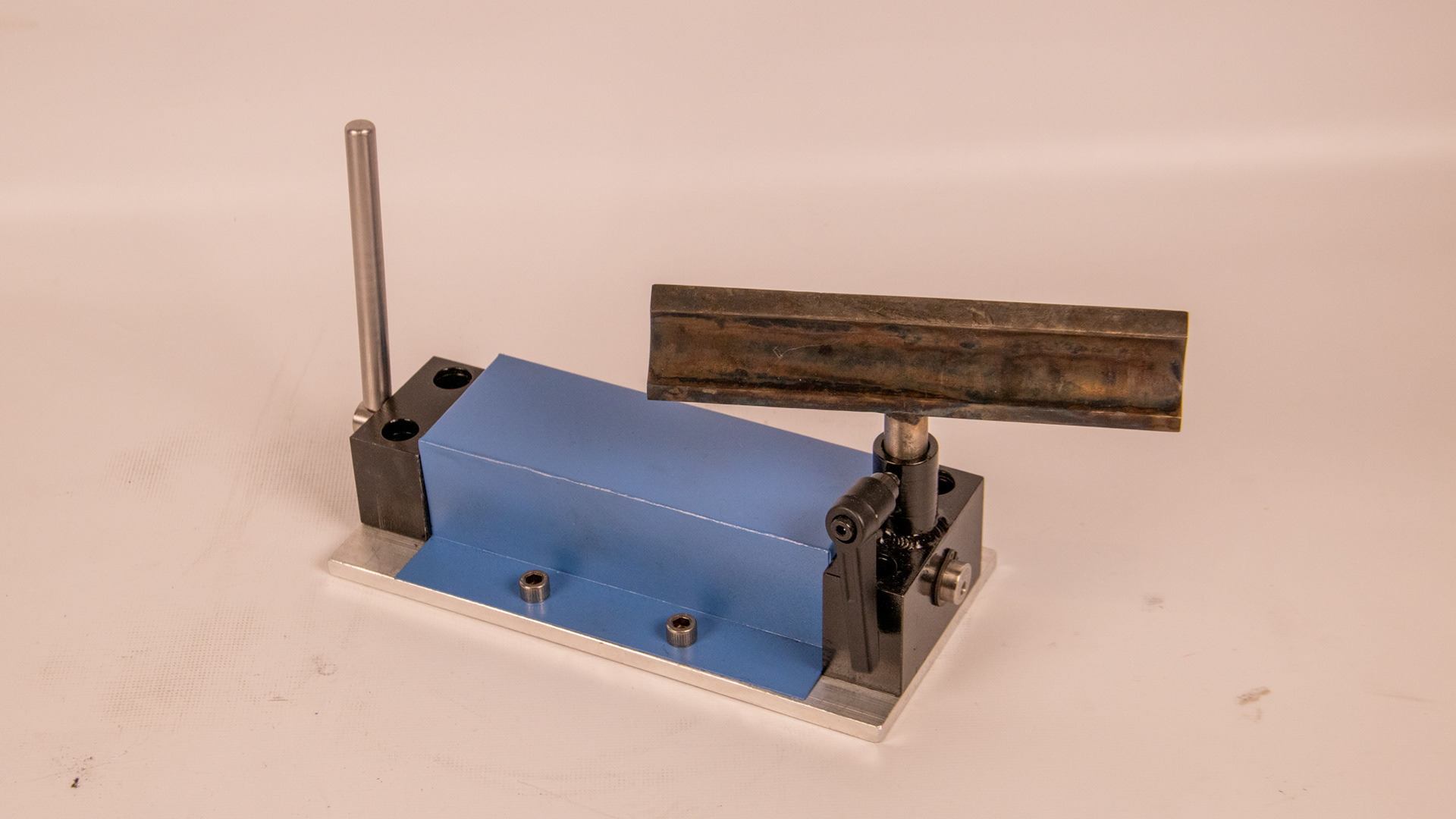

This is one of the eccentric cam locks I designed and machined to hold the tool rest and tail stock in place on the lathe bed.

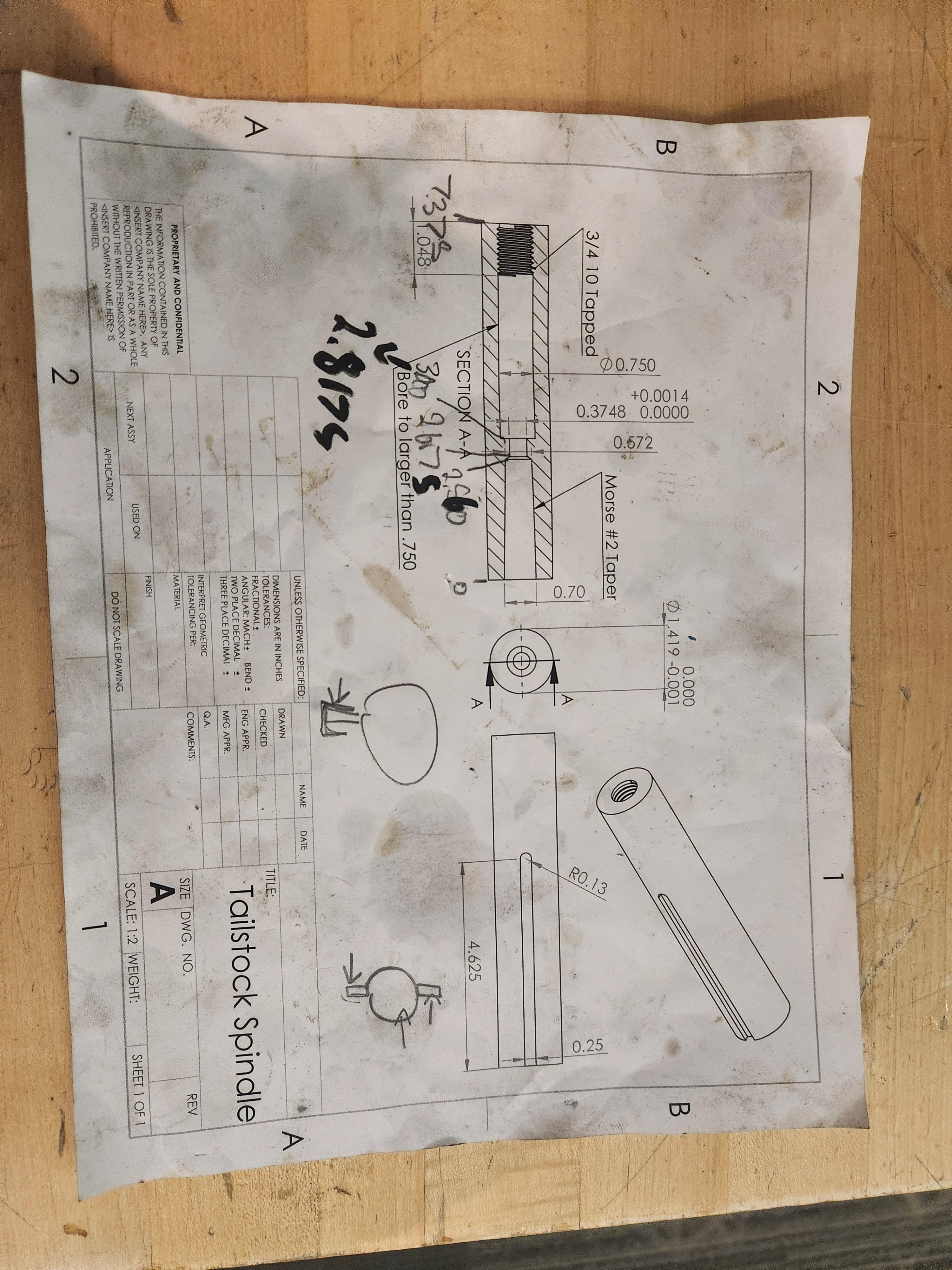

The lathe has many complex parts that required machining that included just about every major type of machining our shop has access to including the mills, lathes, waterjet, plasma cutter, welding, sheet metal bending and more. Here are just a few of the photos from the manufacturing process.